Screen Printing vs. Digital Printing – How These T Shirt Printing Methods Differ?

Technology has developed tremendously over the past years. Things that were impossible to do before are now easily achievable without too much hassle. The t shirt printing industry has benefited heavily from the success and latest advancements in print technology. As such, t shirt printing companies have since moved away from the traditional silk screen printing, opting to use digital equipment instead.

However, there are different aspects to take into account for the uninitiated who are clueless when it comes to the printing industry. Today, there are many options for you to choose from when it comes to customised t shirts. In this article, we will be focusing on two of the most popular t shirt printing methods. They are the traditional silk screen printing and digital printing (also known as Direct to Garment (DTG) printing). Both of which have their individual characteristics.

T Shirt With Silk Screen Printing

Silk screen printing involves creating a silk screen stencil that printers call “screen”. This stencil is being used to apply layers of ink on the printing surface. For designs with multiple colors, each individual color is applied using a different stencil, one at a time. This process is done a few times achieve the final look.

Screen printing is also able to print distinct pantone colors. This is advantageous for companies whose corporate logos follow a unique color tone. It is also the best printing method for designs that require a high level of vibrancy. This trait is especially useful when printing on dark colored t shirts or customised corporate gifts.

The ink being applied is thicker as compared to digital printing which allows brighter colors to be printed even on darker t shirts. As these products are printed by hand, they are able to print over a variety of products such as water bottles, pens, mugs etc. This is made possible because the person printing can manually handle odd shapes like uneven or curved surfaces. The limitation of silk screen printing would be the cost if you are printing for small quantity. There is a MOQ (minimum order quantity) for screen printing. This is because extra materials and labor time needed to carry out this printing method. Therefore it is more economical if silk screen printing in done in as large quantity as possible.

DTG or Digital Printed T-Shirts

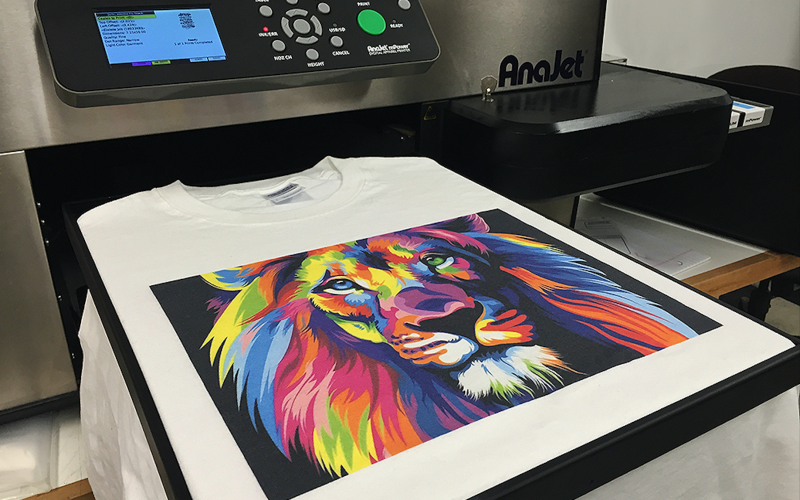

DTG or Digital printing is a newer process that involves your artwork being processed by a computer before it gets printed directly onto the surface of your t shirts. Unlike heat transfer, ink is being directly adhered to the fabric of your t shirt. The biggest attribute of digital printing is its ability to print high amounts of detail. Its multiple colour palettes allow people to recreate anything virtually. As such it is able to print in full color if your design requires so. You are also able to make custom t shirt orders in smaller quantities.

As DTG does not use screens to print, it makes photographics prints possible. This in itself is something that the traditional silk screen printing method cannot achieve. The ink applied to the fabric surface is thinner for it to achieve minute details. Digital printing has the best print texture on white or light coloured t shirt. Due to no additional coating is required before printing is commenced. DTG printing can only be done on cotton material as well. However, there is more freedom for MOQ since there is no physical setup or additional printing materials involved.

The Takeaway

In summary, there is no one printing method that stands out from the other as being the absolute best. Rather, both printing methods have their own strengths and weaknesses. It is up to you to perceive the best t shirt printing option that is the most suitable based on your design. Silk screen printing is still being used by t shirt printing companies and is the most used process to date. Direct to garment or digital process has also become the main alternative for small runs.

TREA is experienced and proud to be able to stand behind both printing methods with 100% confidence. We have a spectrum of products for you to choose from for your ready design. You have our assurance that we will not disappoint.